A Guide to Tools for Quality Management Implementation

Quality management (QM) focuses on ensuring that products and services consistently meet customer expectations. It plays a vital role in improving customer service by streamlining processes and reducing errors. Operational efficiency also benefits from QM, as it identifies inefficiencies and optimizes workflows.

Tools and systems are essential for implementing QM effectively. For instance, a quality management system can reduce human errors through features like document control and structured data forms. Organizations with mature QM systems often achieve higher on-time delivery rates, enhancing customer satisfaction. Sobot, a leader in contact center solutions, exemplifies how technology can transform quality management practices.

📊 Did you know? The global QMS market is projected to grow from USD 8.68 billion in 2021 to USD 21.4 billion by 2030, reflecting its increasing adoption across industries.

Essential Tools for Quality Management Systems

Implementing a quality management system requires the right tools and methodologies to ensure success. These tools streamline processes, enhance efficiency, and improve customer satisfaction. Below, you’ll find an overview of essential software, methodologies, and frameworks that support quality management systems.

Software Tools for QMS

Quality Management Systems (QMS) Software

QMS software forms the backbone of quality management systems. It helps you manage documents, audits, and supplier relationships while providing analytics for informed decision-making. Different industries use specialized QMS software tailored to their needs. For example:

| Type of QMS Software | Key Features |

|---|---|

| General QMS systems | Document management, audit management, supplier management, analytics. |

| Aerospace QMS systems | Adherence to AS9100 standards for product design and manufacturing. |

| Automotive QMS systems | Compliance with NHTSA quality standards throughout the supply chain. |

| Food and agriculture QMS systems | Compliance with HACCP principles for food safety regulations. |

| Healthcare and Medical QMS systems | Compliance with ISO 13485 for medical device regulations. |

| IT QMS systems | Management of IT systems according to ISO/IEC 27001 standards. |

| Pharmaceutical QMS systems | Adherence to FDA 21 CFR Part 11 and ISO guidelines for pharmaceuticals. |

Customer Feedback and Survey Tools

Customer feedback tools allow you to gather insights directly from your audience. These tools help you identify areas for improvement and track customer satisfaction over time. Features like survey customization, real-time analytics, and integration with other systems make them indispensable for quality assurance.

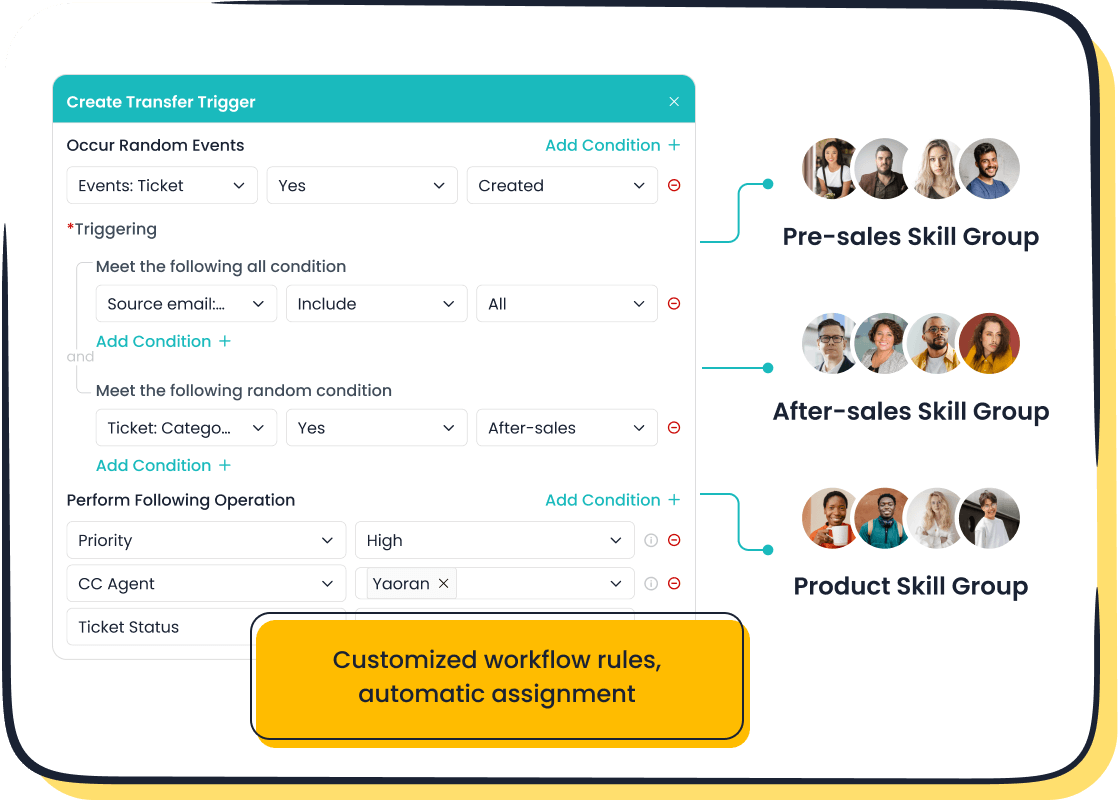

Workflow Automation Tools

Workflow automation tools simplify repetitive tasks, ensuring consistency and reducing errors. For instance, Sobot’s Ticketing System automates ticket creation and routing, helping you manage customer interactions efficiently. Its SLA management and analytics features ensure timely responses and improved service quality.

Methodologies for Quality Management

Six Sigma

Six Sigma focuses on reducing process variation and improving quality. Its principles include customer satisfaction, data-driven decisions, and continuous improvement. Organizations using Six Sigma monitor processes and make incremental changes to maintain high performance.

💡 Tip: Six Sigma emphasizes sustained improvement, ensuring processes evolve to meet customer needs.

Total Quality Management (TQM)

TQM promotes a company-wide focus on quality improvement. It empowers employees to take ownership of quality assurance and fosters a culture of continuous enhancement. This methodology aligns well with long-term business goals.

Lean Management

Lean management aims to eliminate waste and improve efficiency. It shares similarities with TQM but prioritizes speed and resource optimization. By focusing on value-added activities, Lean helps you streamline operations and reduce costs.

Frameworks for Implementing QMS

ISO 9001 Standards

ISO 9001 compliance ensures your processes meet global quality standards. It integrates better process management, evidence-based decision-making, and a culture of continual improvement. This framework enhances credibility and customer satisfaction, making it a cornerstone of quality management systems.

Baldrige Excellence Framework

The Baldrige Excellence Framework helps you align strategic planning with customer focus. It emphasizes organizational unity, workforce development, and leadership ethics. By adopting this framework, you can foster innovation and achieve long-term success.

| Benefit | Description |

|---|---|

| Long-term strategic planning | Integrates all aspects of a business and its stakeholders into a coordinated strategic plan, ensuring agility and innovation are central. |

| Customer focus | Makes customer focus a strategic element, integrated with planning and innovation. |

| Organizational unity | Encourages working as whole units with coordinated direction to avoid silos. |

Capability Maturity Model Integration (CMMI)

CMMI provides a structured approach to process improvement. It helps you assess your organization’s maturity level and implement practices that enhance efficiency and quality. This framework is particularly useful for IT and software development industries.

Steps to Implement a Quality Management System

Planning and Assessment

Identifying Quality Objectives

The first step in quality management implementation involves identifying the need for a quality management system. You should evaluate your current quality performance and pinpoint gaps that hinder efficiency. Once you understand these gaps, define clear quality objectives. These objectives should align with your organization’s goals and focus on measurable outcomes like reducing errors or improving customer satisfaction. For example, a retail company might aim to reduce product return rates by 20% within six months. Setting these objectives provides a roadmap for your quality management implementation plan.

Evaluating Current Processes

Evaluating your current processes helps you understand where inefficiencies exist. Map out workflows and identify bottlenecks or redundancies. This evaluation forms the foundation for designing the quality management system. For instance, if your customer service team struggles with delayed responses, tools like Sobot’s Ticketing System can automate workflows and improve response times. By addressing these inefficiencies, you can ensure a smoother transition during QMS implementation.

Tool Selection and Customization

Criteria for Selecting Tools

Selecting the right tools is critical for effective implementation. Consider factors like user-friendliness, integration capabilities, scalability, and implementation methods. The table below outlines these criteria:

| Criteria | Description |

|---|---|

| User-friendliness | Ensures that the system is easy to use, which contributes to user acceptance and successful implementation. |

| Integration capabilities | The system should integrate well with existing systems to facilitate data sharing and collaboration. |

| Scalability | The system must be able to grow with the organization, accommodating more users and data over time. |

| Implementation | A proven implementation method is crucial for timely and budget-friendly deployment of the system. |

Sobot’s Ticketing System, for example, excels in integration and scalability, making it a reliable choice for businesses of all sizes.

Customizing Tools for Organizational Needs

Customization ensures that the tools you select align with your organization’s unique requirements. Tailor features like workflows, reporting dashboards, and SLA settings to match your quality objectives. For instance, if your goal is to improve customer satisfaction, you can configure Sobot’s Ticketing System to prioritize high-impact tickets and automate SLA reminders. Customization enhances the system’s effectiveness and ensures it meets your specific needs.

Training and Deployment

Employee Training Programs

Training employees is essential for successful QMS implementation. Engage your team early to foster a quality-first mindset. Use tailored training programs to address the needs of different roles. For example, customer service agents might focus on using tools like Sobot’s Ticketing System, while managers learn to analyze performance metrics. Leverage technology for interactive training sessions and promote continuous learning to keep employees updated on best practices.

Phased Deployment Strategies

A phased deployment minimizes disruptions and ensures a smooth transition. Start with a gradual rollout by implementing the system in manageable sections. Pilot programs in stable departments allow you to refine processes before scaling. Collect feedback during the pilot phase and make necessary adjustments. For example, if a pilot reveals inefficiencies in ticket routing, you can tweak the system before extending it to other departments. This iterative approach ensures effective implementation and long-term success.

Monitoring and Continuous Improvement

Setting KPIs for Quality

Key performance indicators for quality management systems play a crucial role in evaluating the success of your quality management system. These metrics help you measure progress and identify areas for improvement. When setting KPIs, focus on aligning them with your organizational goals. For instance, if your objective is to enhance customer satisfaction, you might track metrics like response time, resolution rate, or customer feedback scores.

To ensure effectiveness, make your KPIs specific, measurable, and actionable. For example, instead of a vague goal like "improve product quality," set a target such as "reduce product defects by 15% within six months." This approach provides clarity and direction for your team. Tools like Sobot’s Ticketing System can assist in tracking these metrics by offering real-time analytics and performance dashboards. By monitoring these indicators, you can drive continuous improvement in quality management systems and achieve long-term success.

Regular Audits and Feedback Loops

Regular audits and feedback loops are essential for continual improvement. Audits help you assess whether your quality management system complies with established standards and identify gaps in implementation. Conducting these audits periodically ensures that your processes remain efficient and effective. For example, a quarterly review of customer service workflows can reveal bottlenecks that hinder response times.

Feedback loops, on the other hand, provide valuable insights from employees and customers. Engaging employees at all levels allows you to leverage their expertise in identifying improvement opportunities. Similarly, customer feedback highlights areas where your products or services may fall short. Combining these insights with audit findings creates a robust framework for continuous improvement.

To streamline this process, consider using tools that integrate feedback collection and audit management. Sobot’s Ticketing System, for instance, offers features like SLA tracking and analytics, which simplify the evaluation of service quality. By fostering a culture of regular assessment and open communication, you can ensure your quality management system evolves to meet changing needs.

Overcoming Challenges in Quality Management Implementation

Implementing a quality management system often comes with hurdles that require strategic solutions. Addressing these challenges ensures a smoother transition and maximizes the benefits of your quality initiatives.

Resistance to Change

Addressing Employee Concerns

Resistance to change is one of the most common obstacles during the implementation of a quality management system. Employees may feel uncertain about new processes or fear additional workloads. To address this, involve your team early in the process. Collect their input to show that their opinions matter. For example, you can organize brainstorming sessions to gather feedback on how the system will impact their roles. Strong leadership and clear communication also play a vital role. Celebrate small wins during the transition to build confidence and maintain morale.

Building a Culture of Quality

Creating a culture of quality ensures long-term success. Start by securing executive buy-in, as leadership sets the tone for organizational priorities. When leaders actively promote quality initiatives, employees are more likely to follow suit. Incorporate quality into daily operations by recognizing and rewarding efforts that align with your objectives. For instance, you can highlight team achievements in improving customer satisfaction during company meetings. This approach fosters a sense of ownership and commitment to quality.

Integration Issues

Ensuring Compatibility with Existing Systems

Integrating a new quality management system with existing tools can be challenging. Compatibility issues often arise, leading to inefficiencies. To overcome this, adopt a phased approach. Begin with critical systems and ensure data consistency across platforms. Automated testing tools can also streamline the validation process, reducing errors. For example, Sobot’s Ticketing System integrates seamlessly with platforms like Shopify, ensuring smooth data flow and efficient operations.

Overcoming Data Silos

Data silos hinder collaboration and decision-making. Breaking down these silos requires centralized systems that unify information. Tools like Sobot’s Ticketing System consolidate customer interactions across channels, providing a single source of truth. This integration improves accessibility and enables teams to make informed decisions. By addressing data silos, you enhance both efficiency and service quality.

Cost and Resource Constraints

Budgeting for Tools and Training

Limited budgets often restrict the implementation of a quality management system. Align your quality objectives with business goals to justify investments. For example, emphasize how reducing errors can lower operational costs. The 1-10-100 rule illustrates this: fixing an issue during design costs $1, while addressing it post-production costs $100. Prioritize tools that offer scalability and long-term value, such as Sobot’s Ticketing System, which automates workflows and reduces manual effort.

Maximizing ROI

Maximizing ROI involves connecting quality initiatives to broader business strategies. Highlight how quality improvements contribute to customer retention and revenue growth. For instance, OPPO achieved a 57% increase in repurchase rates by integrating Sobot’s solutions. Combining budget items, like training and tool implementation, can also reduce costs. Proactive investments in quality not only ensure compliance but also enhance overall business performance.

Benefits of Quality Management Tools and Systems

Improved Efficiency and Productivity

Streamlining Processes

Quality management tools simplify workflows by automating repetitive tasks and centralizing data. For example, tools like Sobot’s Ticketing System eliminate manual ticket routing, saving time and reducing errors. These systems provide real-time insights, enabling you to make swift decisions and address issues proactively. By standardizing processes, you can maintain consistency across departments and improve overall productivity.

| Benefit | Description |

|---|---|

| Efficiency and accuracy | Eliminates manual data entry, streamlining processes and reducing errors, saving administrative time. |

| Real-time insights | Provides instant access to critical information, enabling swift decision-making and corrective actions. |

| Visibility and analysis | Offers custom dashboards and automated trend analysis for deep insights into quality performance. |

| Standardization and consistency | Maintains uniform quality across production lines and facilities through automated processes. |

| Improved collaboration | Facilitates sharing of results across departments, promoting a focus on quality organization-wide. |

| Traceability and compliance | Centralizes quality records for better tracking and regulatory compliance. |

Reducing Errors and Waste

Effective quality management tools help you identify inefficiencies and eliminate waste. Automated systems reduce human errors by ensuring accurate data entry and consistent workflows. For instance, Sobot’s Ticketing System uses AI-powered automation to prioritize tasks and resolve issues faster. This approach minimizes delays and ensures resources are used efficiently, leading to significant cost savings.

Enhanced Compliance and Standards

Meeting Industry Standards

Quality management systems ensure your processes align with industry standards like ISO 9001. These tools provide centralized records, making it easier to track compliance and maintain accountability. Features like automated dashboards and real-time analytics help you monitor performance and implement corrective actions when needed. By adhering to standards, you enhance your organization’s credibility and customer trust.

- Reduces errors and saves administrative time by eliminating manual data entry.

- Provides instant access to critical information, enabling swift decision-making.

- Maintains uniform quality across production lines, crucial for compliance.

- Centralizes quality records for better tracking and regulatory adherence.

Avoiding Regulatory Penalties

Non-compliance can lead to costly penalties and reputational damage. Quality management tools help you stay ahead by ensuring all processes meet regulatory requirements. For example, Sobot’s Ticketing System tracks SLA compliance, ensuring timely responses and avoiding service-level breaches. This proactive approach safeguards your organization from potential fines and enhances operational reliability.

Better Customer Satisfaction

Delivering Consistent Quality

Consistency is key to customer satisfaction. Quality management systems enable you to deliver uniform products and services by standardizing processes. For instance, a QMS reduces quality issues and ensures quicker problem resolution. Tools like Sobot’s Ticketing System allow you to track customer interactions and address concerns efficiently, fostering a positive customer experience.

Building Customer Trust and Loyalty

When customers see consistent quality, they trust your brand more. Engaging with customers through feedback tools helps you understand their needs and improve your offerings. Sobot’s solutions, like its Ticketing System, consolidate customer data, enabling personalized support and faster resolutions. This approach not only builds trust but also encourages repeat business, as seen in OPPO’s 57% increase in repurchase rates after implementing Sobot’s tools.

Tips for Selecting the Right Tools and Ensuring Continuous Improvement

Evaluating Organizational Needs

Aligning Tools with Business Goals

To select the right tools, you must first align them with your business goals. Start by evaluating your process management techniques. Identify your quality management system processes, understand their interactions, and determine criteria for effective operation. Monitoring and analyzing these processes ensures that your tools support your quality objectives. For example, if your goal is to improve customer satisfaction, tools like Sobot’s Ticketing System can help by automating workflows and tracking response times.

Understanding customer needs is equally important. Consult internal and external customers to identify their expectations. This feedback helps measure process outputs and ensures your quality objectives meet customer satisfaction. Lastly, integrate continual improvement activities into your strategy. Use quality policies, objectives, and data analysis to enhance your system’s effectiveness and align it with your business goals.

Considering Scalability and Flexibility

Scalability and flexibility are critical for future-proofing your quality management system. A phased rollout allows you to manage change gradually and gather feedback. Choose scalable software that integrates seamlessly with existing systems. For instance, Sobot’s Ticketing System supports integration with platforms like Shopify, ensuring smooth operations as your business grows.

Promote a culture of continuous improvement to adapt your system over time. This approach ensures your tools remain relevant and effective, even as your organization evolves.

Leveraging Sobot's Ticketing System for QMS

Automating Workflow and SLA Management

Automation is key to improving efficiency in quality management. Sobot’s Ticketing System automates ticket creation, routing, and SLA management. These features reduce manual effort and ensure timely responses. For example, the system can prioritize high-impact tickets and send SLA reminders, helping you maintain service quality. Its AI-powered tools also enhance accuracy, making it easier to meet your quality objectives.

Enhancing Customer Support Efficiency

Efficient customer support is vital for maintaining quality. Sobot’s Ticketing System consolidates customer interactions across channels, providing a unified view of each case. This integration reduces response times and improves resolution rates. For example, OPPO achieved an 83% chatbot resolution rate and a 94% positive feedback rate by using Sobot’s solutions. These results highlight how the system can enhance both efficiency and customer satisfaction.

Fostering a Quality-First Mindset

Leadership Commitment

Strong leadership is essential for fostering a quality-first mindset. Leaders must define company values and integrate them into daily operations. For example, promoting quality as a core value encourages employees to prioritize it in their work. Leaders should also communicate the importance of quality initiatives and lead by example to inspire their teams.

Employee Engagement

Engaged employees are more likely to embrace quality initiatives. Provide regular training to enhance their understanding of quality standards. Workshops and coaching sessions can help employees adopt a quality-first approach. Additionally, collect feedback from your team to identify areas for improvement. This collaborative approach ensures everyone contributes to maintaining a high-quality system.

Staying Updated on Emerging Tools

Investing in Data-Driven Decision Making

Staying competitive in today’s market requires you to embrace data-driven decision-making. This approach ensures that your quality management system operates with precision and reliability. By leveraging real-time data, you can monitor key performance indicators (KPIs) and make informed decisions that enhance your processes. For example, advanced analytics tools allow you to track metrics like defect rates or customer satisfaction scores, ensuring your system aligns with organizational goals.

Emerging technologies like no-code AI platforms simplify data cleaning and matching, making these processes more accessible. Real-time data quality monitoring has also become essential for maintaining data integrity. This ensures that the insights you generate are accurate and actionable. Additionally, cloud-native platforms provide scalability and accessibility, enabling you to manage your quality system efficiently across multiple locations. Integrating IoT devices further enhances this capability by offering real-time monitoring of production processes, which is vital for maintaining consistent quality.

Exploring AI and Automation Solutions

Artificial intelligence (AI) and automation are transforming how you manage quality. These technologies streamline workflows, reduce errors, and improve efficiency. For instance, AI-driven tools can analyze large datasets to provide predictive insights, helping you identify potential issues before they escalate. Automation enhances this process by continuously improving workflows and eliminating repetitive tasks.

IoT-enabled quality monitoring is another game-changer. Connected devices provide real-time data, allowing you to detect quality issues faster and make better decisions. For example, Sobot’s Ticketing System uses AI-powered automation to prioritize tasks and manage service-level agreements (SLAs). This ensures timely responses and enhances customer satisfaction. By adopting these solutions, you can create a more agile and effective quality management system that adapts to evolving business needs.

🚀 Pro Tip: Combining AI with automation not only improves efficiency but also ensures your system remains future-ready.

Implementing a robust quality management system is essential for achieving operational excellence and customer satisfaction. Tools and systems streamline processes, reduce errors, and foster a culture of continuous improvement. For example, organizations that adopt structured frameworks like ISO 9001 or digital tools often see measurable benefits, such as increased efficiency and reduced risks.

Sobot’s Ticketing System exemplifies how technology enhances quality management. Its features, like automated workflows and SLA tracking, improve service efficiency and ensure consistent quality. Companies like OPPO have leveraged such tools to achieve higher customer satisfaction and operational reliability.

To succeed, you must adopt a strategic approach to tool selection. Focus on usability, scalability, and integration capabilities. Digital tools, like Sobot’s, enable data-driven decision-making and real-time visibility, ensuring your system evolves with your needs. Prioritize continuous improvement to maintain a competitive edge and deliver lasting value.

FAQ

What is the purpose of a quality management system?

A quality management system helps you streamline processes, reduce errors, and ensure consistent service delivery. It aligns your operations with industry standards, improving customer satisfaction and operational efficiency. For example, ISO 9001-certified systems enhance credibility and compliance.

How does automation improve quality management?

Automation reduces manual tasks, ensuring accuracy and efficiency. Tools like Sobot’s Ticketing System automate workflows, prioritize tasks, and track SLAs. This approach minimizes errors and enhances service quality, as seen in OPPO’s 83% chatbot resolution rate.

Can a quality management system integrate with existing tools?

Yes, most systems integrate seamlessly with existing platforms. For instance, Sobot’s Ticketing System connects with Shopify and other e-commerce tools, ensuring smooth data flow and unified operations.

How do you measure the success of a quality management system?

You measure success using KPIs like response time, resolution rate, and customer satisfaction scores. Tools like Sobot’s Ticketing System provide real-time analytics, helping you track these metrics and identify areas for improvement.

Why is employee training essential for quality management?

Training ensures employees understand the system and its processes. It fosters a quality-first mindset and boosts efficiency. For example, training on Sobot’s Ticketing System helps agents resolve tickets faster, improving customer satisfaction.

See Also

Essential QMS Strategies for Effective Call Center Management

Navigating Quality Assurance Tools for Call Centers

Top Strategies for Quality Management in Call Centers